Mufflers

“Ultra-Quiet”TM Muffler

Pore Technology’s Ultra Quiet porous plastic mufflers and silencers are the most effective available. Our mufflers are made with sandard sized male NPT threads (custom female threads also available). Made here at our Texas faicilty using the highest quality virgin polyethylene.

- Available in sizes: 10/32″, 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, and 1″ NPT.

- Independant tests show that Pore Technology;s mufflers are at least 20% quiter than other porous plastic mufflers and silencers.

- Water and oil will not harm our Ultra Quiet Mufflers.

- Working Pressure up to 100 PSI

- Porous high density polyethylene will not shatter in of accidental rupture.

- Easily cleaned.

- Available in two porosities, standard and High Flow.

“Ultra-Quiet”TM Technical Data

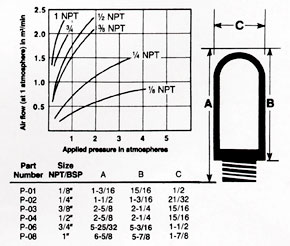

Octave band frequencies in kHz – Combination thread fits either BSP or NPT

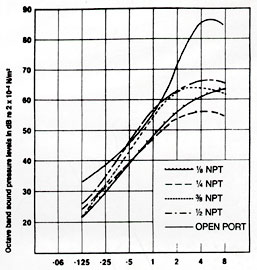

Fig. 1: Attenuation of Sound by Pore Technology Ultra-Quiet Mufflers (at an air pressure of 5.7 atmosphere)

Sound

Comprehensive measurements have been made to determine the effectiveness of the Pore Technology Muffler.

The noise from a single un-muffled exhaust port is reduced from about 90 dB(A) to between 60 and 70 dB(A) when fitted with a Pore Technology Muffler. The actual reduction in noise with this range depends upon particular installations, the size and working pressure.

But the reduction is significant. 90dB(A) corresponds to the noise produced by a heavy truck or underground train passing at a distance of a few feet and represents the acknowledged danger level to which people should not be exposed for any length of time. By comparison 60 dB(A) corresponds to normal conversion at a distance of 3 feet.

The dB(A) scale corresponds fairly closely to the subjective human hearing experience

and allows for the fact that the greatest sensitivity of the human ear occurs in the region 1000 to 4000 Hz.

The curves shown in Fig. 1 are a frequency analysis of the noise produced by the exhaust port of a valve with and without a muffler. The sound pressure level in each octave band is measured by four microphones in a one meter circle around the source. The curves represent the distribution of sound in each of the octave bands. It can be deduced from these that the difference between the un-muffled port and the muffled port is much higher at the 2,4 and 8 kHz level. The performance of the mufflers is fairly constant from size to size, the smaller ones being slightly more efficient.

Air Flow

The effect of the muffler on piston speed varies from effectively zero in a very large number of installations to a maximum of 10-15% Permeabilities are shown in Fig. 2.

The method by which the mufflers have been tested for airflow can be found in BS1042 Part 1 “Methods for the Measurement of Fluid Flow in Pipes.” This is a method using an orifice plate in a pipe. The air from the muffler is passed through a pipe and is restricted by the orifice plate, measurement of which gives, by means of a formula, the air flow through the pipe, and hence through the muffler. There are two advantages to this method. It is close to an absolute method in that it does not rely on any other instruments or meters for its accuracy. Second, flow rate is given by the formula in terms of mass per unit time. This can then be converted to volume flow at any desired pressure without the confliction of compression effects that follow from measuring volume flow direct.