Resins used in the production of porous plastics affect the ultimate parts strength, wettability, bio-compatibility, porosity, and effective filtration.

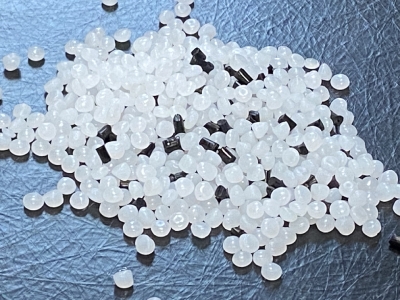

The primary material we use to make porous plastic parts is polyethylene, and specifically HDPE, VHDPE, and UHMWPE. The increased molecular weight of these materials improves part strength and wear resistance. PE is inert and there are no effective solvents to dissolve it at room temperature. Some chemicals and environmental conditions can lead to oxidization and deterioration of it’s mechanical properties, but some of these can be mitigated. It works well for industrial applications and even for biomaterials. All of our grades of PE are RoHS and REACH compliant, and approved for use with food (FDA regulation 21 CFR 177.1520).

Some additional materials we use are;

- Polypropylene (PP)

- Polyvinylidene Difluoride (PVDF)

- Polytetrafluoroethylene (PTFE)